The Sterile Packaging Market is estimated to be valued at US$ 41.14 Bn in 2031

- Ronak Shah

- U.S.A

- January 30, 2025

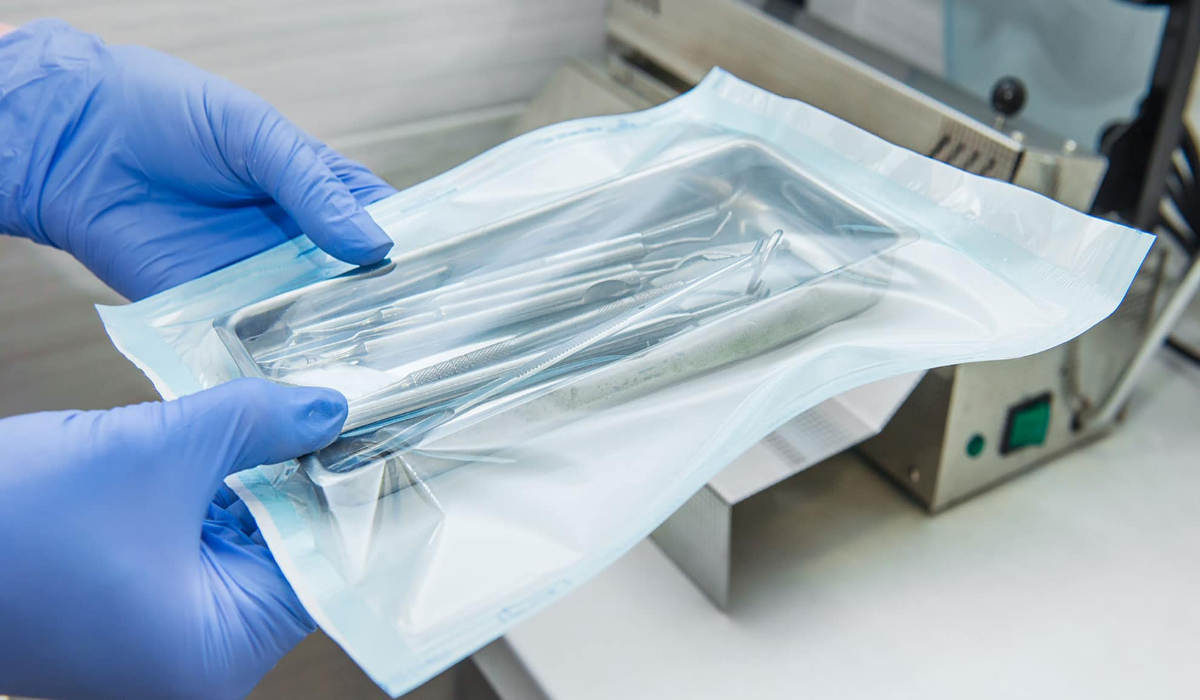

A newly published report by Coherent Market Insights reveals a sustainable growth opportunity in the sterile packaging market. Coherent Market Insights’ analyst projected the sterile packaging market to be valued at US$ 41.14 Bn in 2031. It is expected to exhibit a CAGR of 5.7% over the forecast period 2024-2031.

Sterility in pharmaceutical and medical device packaging creates an increased demand within the market. Sterile packaging ensures that medical devices and pharmaceutical products remain sterile by not allowing pathogens from the outside environment.

With increasing prevalence of chronic diseases, a rapidly aging population, and thus increased healthcare expenditure worldwide, the demand for sterile medical products increases, driving the growth of the sterile packaging market. In addition to that, there are improvements in the technological side with regard to sterile barrier systems and packaging materials, which enhance the growth in this market.

Key market trends include Adoption of Eco-Friendly Packaging Materials- Growing environmental concerns have shifted the preference of pharmaceutical and medical device manufacturers towards sustainable sterile packaging solutions. Adoption of recyclable and biodegradable materials such as paper & paperboard, recycled plastics, and biomaterials for sterile barrier system and packages is on the rise.

Personalization of Healthcare- Advances in 3D printing, artificial intelligence, and virtual reality are enabling personalization of healthcare. Emerging technologies are allowing customized designs of medical devices and tailored medications according to patient’s specific needs and conditions. This trend requires flexible and customized sterile packaging configurations to effectively package and deliver personalized products.

Sterile Packaging Market Opportunities: Flat packaging solutions such as pouches, bags, and sachets are in high demand for sterile medical packaging. Their flat and flexible nature allows for compact storage and shipping. Key advantages include lower production costs compared to rigid alternatives as well as the ability to form around odd-shaped items. They provide an effective barrier against contaminants and are commonly used for drug packaging.

Thermoform packaging involves sealing pre-sterilized components inside plastic trays formed through heat sealing. They maintain sterility throughout transportation and storage while allowing visibility of the product. Growing surgical volumes and new medical device approvals are fueling demand for thermoform packaging.

Key Market Takeaways: The global sterile packaging market size is anticipated to reach USD 41.14 Billion by 2031 registering a CAGR of 5.7% during the forecast period. Increased healthcare spending and stringent regulations regarding sterility of medicinal products is driving market growth.

Based on packaging type, flat packaging is expected to hold the largest share. This is owing to lower costs and flexibility to form around varied shapes.

Within flat packaging, pouches & reels contribute over 30% of the segment. This owing to widespread usage for drug products.

By material, plastic is projected to dominate the market and account for over 45% share. This is due to characteristics like transparency, durability and moisture resistance required in medical packaging.

North America is projected to lead regional growth over the forecast period. This is due to advanced healthcare infrastructure and stringent medical standards in the region.

Competitor Insights: Key players operating in the market include Amcor plc, Berry Global, Inc., Sealed Air Corporation, and DuPont de Nemours, Inc.

Recent Developments: In June 2024, Coveris, a prominent supplier of packaging solutions with headquarters in Europe, introduced its MonoFlex Fibre line, a state-of-the-art functional paper solution designed for primary and secondary packaging. By combining improved barrier qualities with higher sealing capabilities, the product exemplifies Coveris’ dedication to practical and sustainable packaging advances. More information in full report