Metals Stamping Market Is Estimated To Witness High Growth Owing To Increasing Demand for Automobiles

- Ronak Shah

- U.S.A

- January 14, 2025

The Metals Stamping Market is estimated to be valued at US$ 222.14 Bn in 2024 and is expected to exhibit a CAGR of 3.9% over the forecast period 2024- 2031, as highlighted in a new report published by Coherent Market Insights.

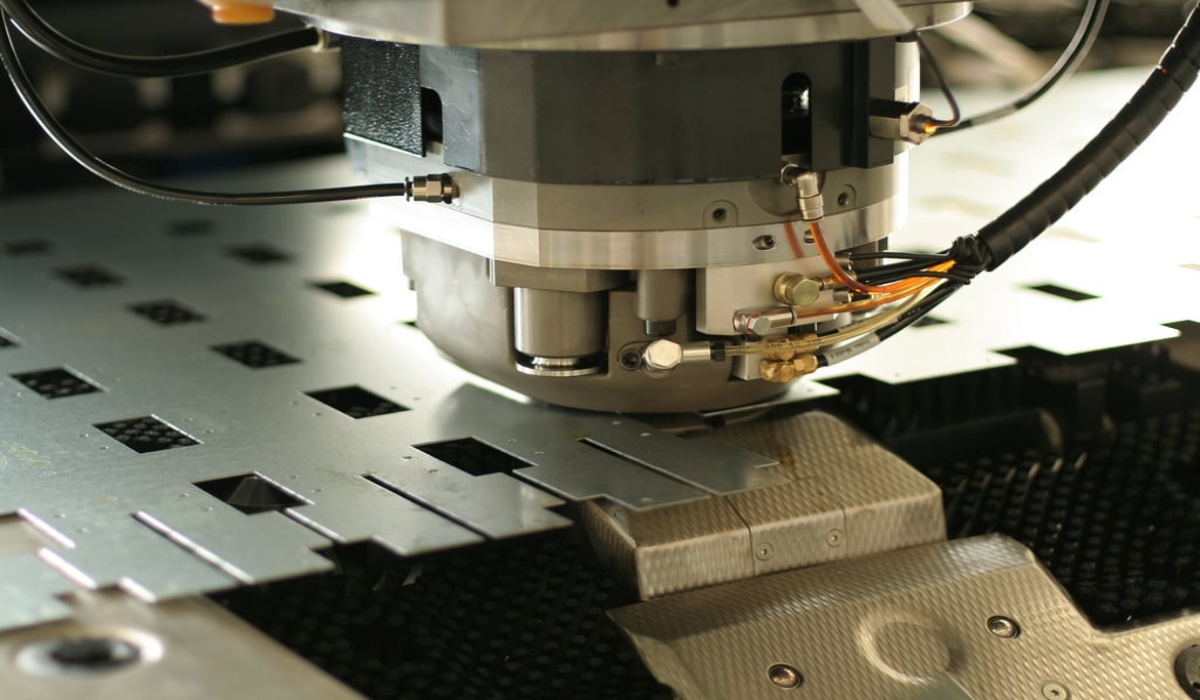

The Metals Stamping Market is driven by increasing demand for automobiles globally and technological advancements in metals stamping processes. Automotive production has been increasing steadily, with developing regions such as Asia Pacific witnessing high growth. Rising automobile demand positively impacts the metals stamping market. New technology developments allow for improved productivity, reduced wastage, multi-dimensional stamping, and more complex part production.

Key Market Trends: Growing preference for lightweight vehicles to increase fuel efficiency is a major trend in the metals stamping market. Automakers are focusing on reducing vehicle weight to meet stringent emission norms. Metals such as aluminum and high-strength steel allow for weight reduction compared to conventional steel and are increasingly used in body panels and structural components. Another trend is the increasing adoption of smart manufacturing technologies such as 3D printing, AI, robotics, and the internet of things (IoT) in metals stamping processes. These technologies help improve production efficiency and precision, reduce errors, enhance quality control, and enable mass customization. Get full sample of the report here.

Market Opportunities and Outlook: Automotive Sector – The automotive industry is one of the major end-users of metal stamping. Growing vehicle production worldwide is fueling the demand for various metal components like door panels, hoods, brackets etc. that are manufactured through stamping. Growing preference for lightweight vehicles to improve fuel efficiency is also increasing the usage of advanced high strength steel and aluminum alloys in the automotive industry which is benefiting the metal stamping market.

Electronics Industry – The electronics industry is rapidly adopting metal stamping to manufacture various components for devices like mobile phones, laptops, household appliances etc. Miniaturization of electronic products has increased the demand for intricate and highly precise stamped metal parts. Growing production of consumer electronics is thus presenting lucrative opportunities for metal stamping manufacturers.

Key Market Takeaways: The global metals stamping market is anticipated to witness a CAGR of 3.9% during the forecast period 2024-2031, owing to growing automotive production and electronics manufacturing worldwide. On the basis of process, blanking segment is expected to hold a dominant position, owing to its widespread usage for mass production of common components.

On the basis of press type, mechanical press segment currently dominates the market but hydraulic presses are seeing higher adoption driven by advantages like productivity and automation. Regionally, North America is expected to hold a dominant position over the forecast period, due to presence of major automotive companies in the US and Canada.

Key Players in the Market: CAPARPO, Gestamp, Bokers INC

Recent Developments in Metals Stamping Market: In June 2024, TRUMPF debuted the first large electric press installations at two Midwestern stamping plants. The 1500-ton and 2000-ton presses are driven by energy-efficient direct drives and regenerative braking systems that capture over 90% of kinetic energy during the punch stroke to power other equipment functions or return power to the grid. It is estimated the electric presses will reduce each facility’s energy usage by 25-30% compared to similarly sized hydraulic machines.

In 2023-2024, stampers of all sizes will increase digitization initiatives focusing on areas like real-time production monitoring, predictive quality control, digital work instructions, cloud-based asset performance management, and data-driven process optimization. This will allow for more flexible just-in-time operations, rapid process problem-solving, remote equipment monitoring, and performance benchmarking against KPIs. Press manufacturers are complementing new equipment sales with digital ‘bolt-on’ upgrade packages that convert existing tooling/machinery into networked smart factories with cloud connectivity. The exchange of design and manufacturing data will further seamless collaboration between metal fabricators and their automotive, appliance, electronics customers. Over the next year, digital transformation projects are expected to move beyond individual pilot deployments to formal enterprise-wide roadmaps across progressive stamping companies. Get full coverage of the report here.